Polyurethane Super Abrasion Resistant Top Coat is a high solids, three component polyurethane floor cover coat, which is divided into colored top coat and clear top coat. The cured coating has superb abrasion resistance, excellent weatherability and good adhesion, as well as good chemical resistance and anti-slip properties.

Scope of application:

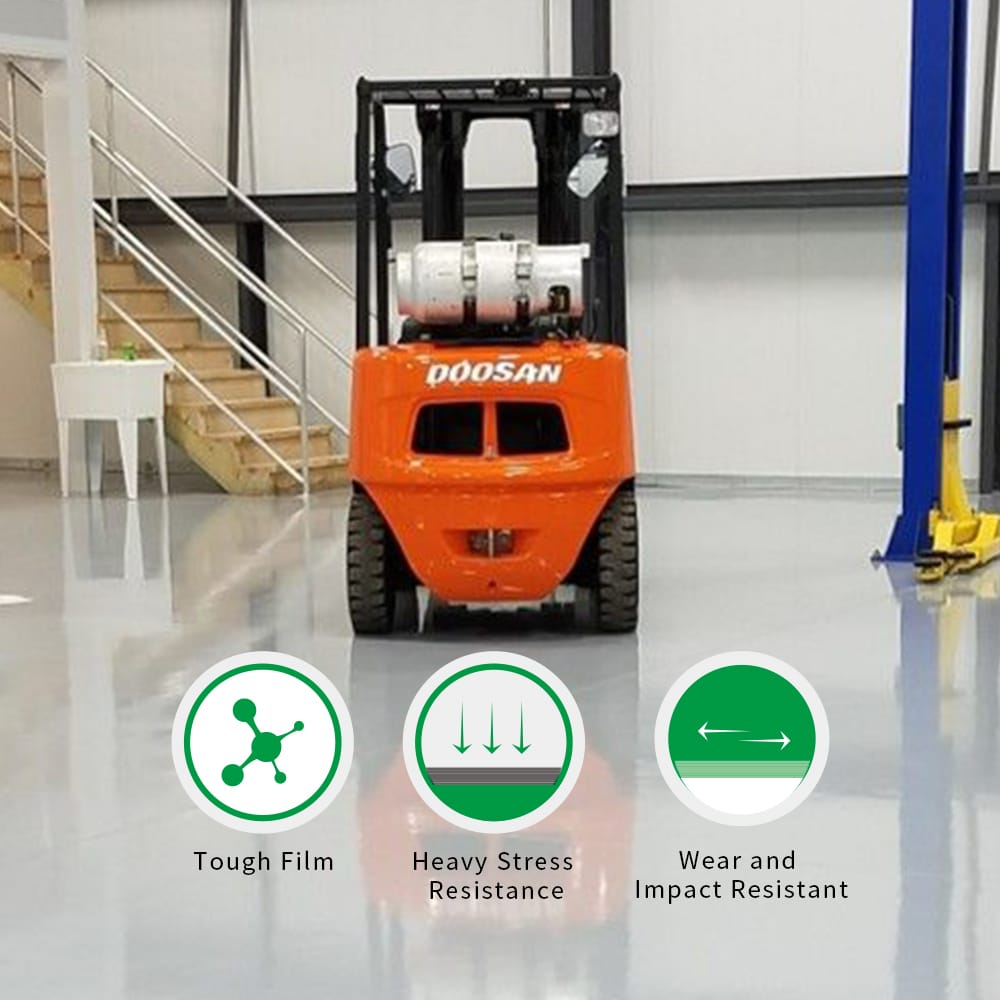

★Indoor and outdoor are available, especially suitable for parking lots, heavy load workshops and other places that need anti-slip and high wear resistance.

Performance features:

★Excellent abrasion resistance (5 times more than ordinary epoxy);

★Non-slip, matte surface;

★Excellent resistance to pressure, folding, impact and chemical corrosion;

★UV resistance, yellowing resistance;

Construction precautions:

1、Construction conditions: humidity less than 80%, temperature 10 ~ 35 ℃, humid environment prohibited construction.

2, the foundation requirements: general construction in the epoxy self-leveling, self-leveling surface needs to be finer resin abrasive pads or sandpaper lightly sanded, the flatness of the foundation will affect the cover paint beautiful.

3、Eliminate the roller coating marks and joint bright marks:

① a person scraping paint, a person rolling paint (perpendicular to the direction of scraping paint, it is recommended to tie heavy objects), the third person wearing spiked shoes to go up with 18 inch short hair roller and scraping in the same direction backward to collect the roll, do not force.

② scrape the paint, joints left about 5 centimeters spacing do not scrape the paint, roll the paint can be rolled up.

③ Joints should not be too long, joints with a roll of paint to collect one or two times to cover the paint can be, do not repeatedly collect, otherwise there will be joints bright marks.

4、After construction: under standard conditions (25℃,50%), it can be put on people after 1 day, and can bear heavy pressure after 3 days. If the temperature is low then need to extend the opening time.